Not known Details About 24hr Media

Table of ContentsNot known Incorrect Statements About 24hr Media 24hr Media for BeginnersThe Facts About 24hr Media UncoveredRumored Buzz on 24hr MediaThe Of 24hr Media

Improvements in print innovation are altering the communications playing area when it involves high quality, affordability and advanced capacities. Balanced out printing and electronic printing are the significant procedures whereby print work are undertaken both utilizing four-color printing methods. Each option has its benefits, using different strategies to satisfy the needs of varied production projects.

Generally, this has been the most consistent technique for precisely maintaining color matches, making it optimal for print runs that only require fixed printing such as pre-printed kinds, sales brochures, leaflets, organization cards, and mass postcard mailings. Due to the fixed nature of litho printing, it is not suitable for variable print pieces that will be sent by mail to private recipients such as statements, letters, and customized postcards.

The Single Strategy To Use For 24hr Media

The most recent advancements in print innovation are assisting to bring numerous of countered's benefits right into the electronic printing globe absolutely transforming the face of modern-day printing! There are some key differences in between Offset Printing and Digital Printing.

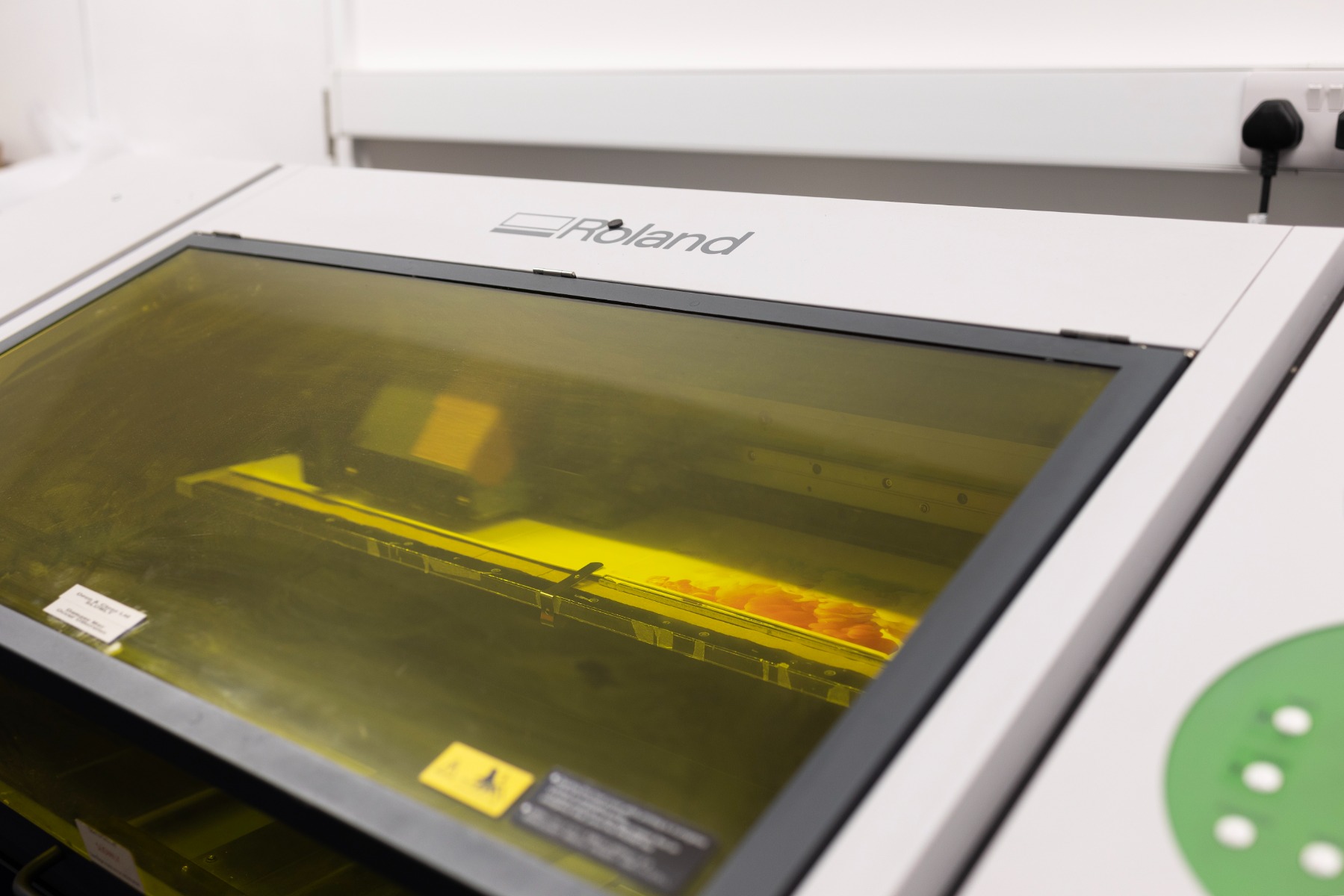

Today's digital print devices is amongst one of the most cutting-edge on the market. Here are some of the greatest benefits of utilizing electronic printing: control the electronic print room, with full-color printing finished in one procedure and flawlessly published straight from a print data. Without a prolonged set-up process, the calibration time of a particular job is shortened, adding to quicker print time and total distribution.

The inkjet printing procedure has helped to revolutionize the industry along with the top quality and rate of the output. The current inkjet technology can publish on typical balanced out supplies with plain, silk, and shiny surfaces. Premium digital print coupled with software-managed shade administration practices adds optimum value to print items and makes production processes extra reputable than balanced out.

The Ultimate Guide To 24hr Media

(https://za24media.carrd.co/)

Environmentally friendly and biodegradable inks and toners are likewise available for more sustainable printing. Digital print also removes the demand to clean plates or blankets with harmful chemicals at the end of the printing procedure.

Variable visite site information helps organizations reach their specific customers and target market with uniquely-created and personalized web content. As innovation improves, the top quality of digital printing has actually ended up being second-to-none, with better detail, shade match capacities and general accuracy. Without the requirement to clean plates or use excess ink, electronic printing is also much less wasteful and normally more eco-friendly.

("flexo"), include numerous make-ready actions to move an initial image to a substrate.

Some Known Details About 24hr Media

Digital printing, with less relocating pieces, is much more agile than offset in this respect.

Decreased set-up time saves money on the front end. And given that these are not substantial mass orders, smaller sized businesses can manage to print without having to fulfill the higher and extra costly print limits of conventional printing.

Make sure you work together with a printing and packaging partner that has the best certifications. While eleventh-hour printing and personalization are a big advantage, electronic may not always be the ideal technique for you. For instance, counter printing has the advantage of cost-effectiveness with big print runs, especially those with innovative attractive results and specialized layers.

24hr Media Things To Know Before You Buy

Lithographic presses use two print platesa positive and a negativeto transfer high-grade shade graphics onto an appropriate substrate. The favorable plate, with its smooth surface, brings in oil-based inks and repels water. In contrast, the unfavorable plate, with its rough texture, absorbs water and drives away oil. Rubber rollers are after that used to transfer the image from home plate to the corrugated surface area.

Corrugated paper can in some cases prove to be a challenging surface to publish on, however Litho prints to a different surface area and is then laminated flooring to it, making it simple to print high-quality pictures. It can be very consistent, even for long terms. The more you publish, the less expensive the prices come to be for Litho.

What Litho does not offer you is specifically what Digital does, modification. Expensive set up Longer turnaround No Variable Information Printing Smaller shade range, colors can be much less intense Digital printing is the process of printing digital images directly onto the corrugated substratum using a single-pass, direct-to-corrugate strategy.